免费a级毛片_任你干精品_国产情侣偷国语对白_插美女视频

| Home | Products | Company | Support | Download | Videos | Employment | Contact | Chinese |

Applications of Waterjet machine:

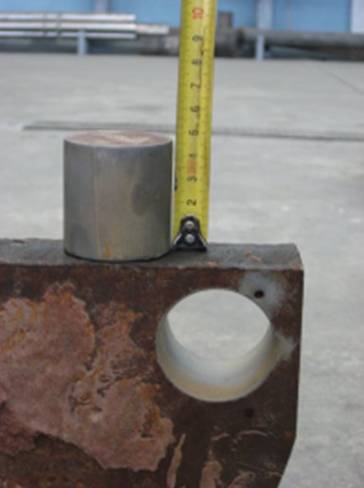

1. Metal: waterjet can cut thin or thick metal such as stainless steel, carbon steel, titanium, aluminum, brass, etc. Advantage: waterjet is cold cut equipment, no heat affected zone, good

edge quality and small cutting gap (~

2. Composite material: Waterjet can cut composite (multiple layers) materials. Advantage: same setup for cutting different layers at the same time. No need to change tool, and

Composite material (two sheet

metal layers with insulating foam in the middle) 3.

Marble, granite, ceramic tile and

Mosaics: Waterjet can precisely cut stone products

to produce inlaid medallion designs for building decoration, and counter tops as

well as tile and mosaic designs. Marble inlaid floor design marble medallion.

Granite counter top

Mosaic fish design 4.

Glass: waterjet can easily piece and cut glass

with good edge quality. The most beautiful part of waterjet is that waterjet is CNC controlled and

it can quickly Advantage: arbitrary geometry cutting is one

of the biggest advantages of the waterjet machine. It

is very useful in cutting glass with holes and special design shapes.

5.

Rubber,

nylon and other low melting point and easy combustion material: Water jets are commonly used for custom gasket cutting, due to the

machine is capable of fast setup and quick turn around. Waterjets cutting will not burn

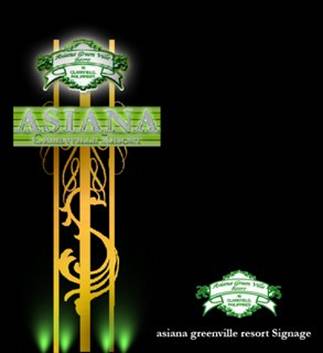

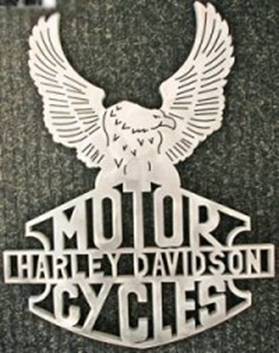

Rubber products cut by waterjet 6.Signage and art works Signage and art works are often of small quality jobs, so waterjets are particularly useful due to its fast CNC setup and easy fixture.

Special door

design and cut by waterjet |

|

|

|

Copyright Nanjing Bitong Technology Co., Ltd.

? All Rights Reserved. 備案號(hào):蘇ICP備08003750號(hào)-1 |